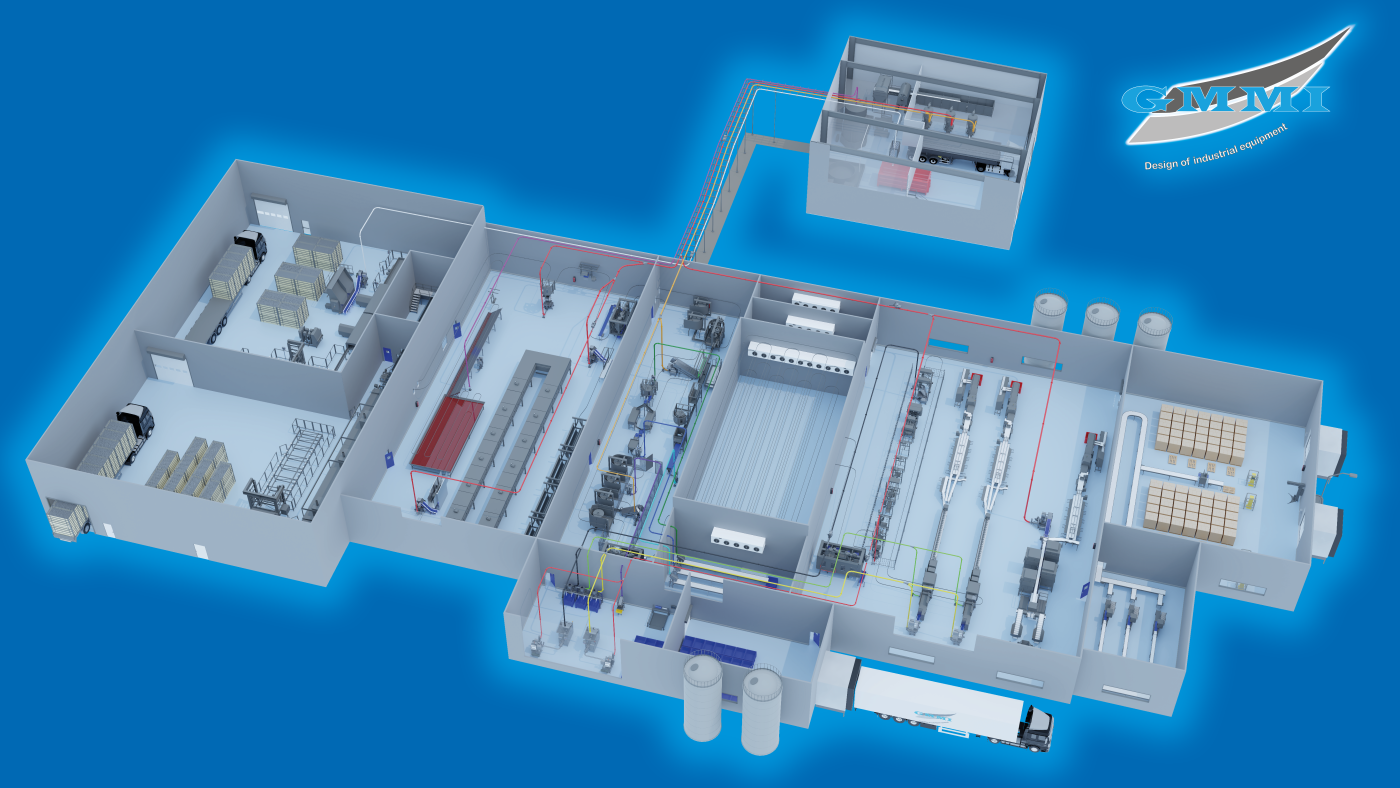

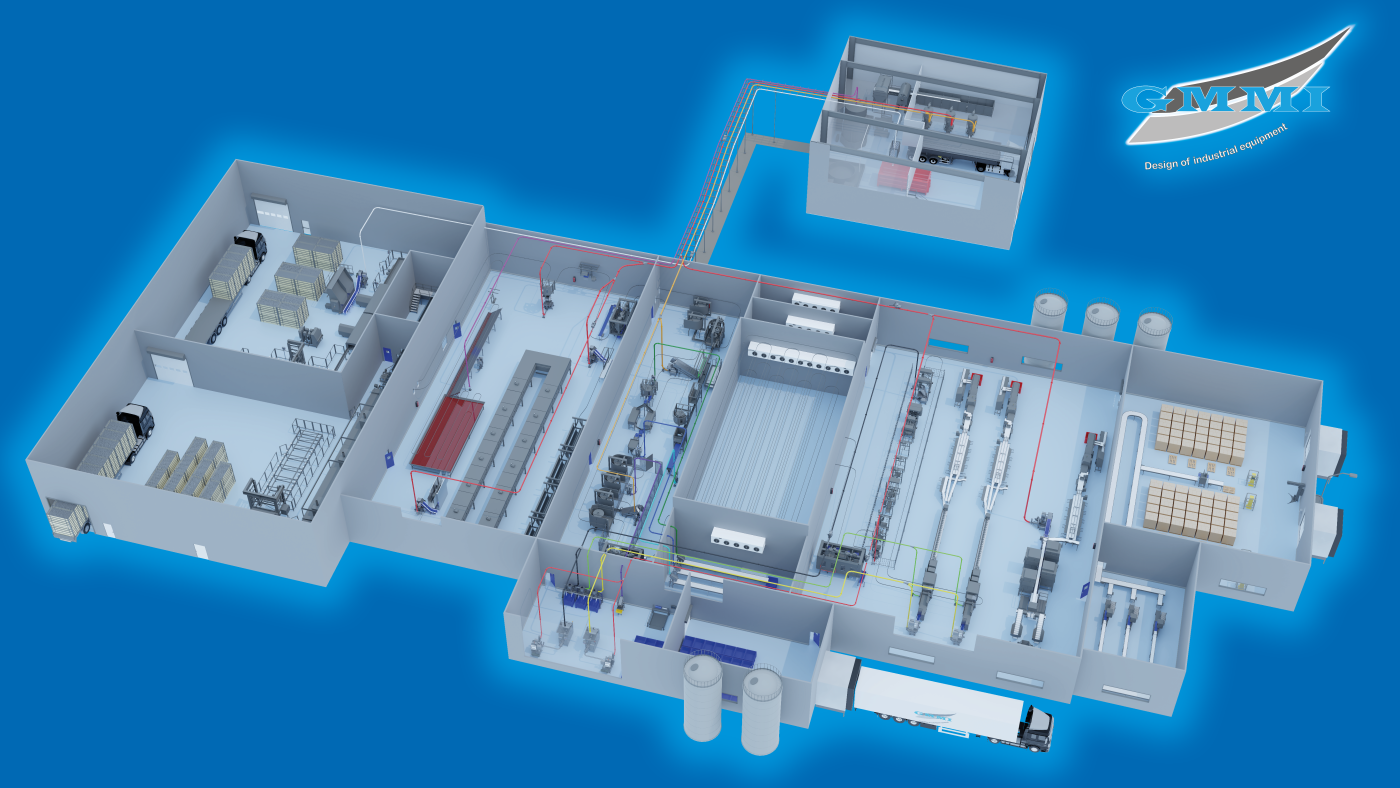

CONCEPTION D’ÉQUIPEMENTS INDUSTRIELS

SYSTÈME DE TRANSFERT PAR TUYAUTERIE / Système de manutention mécanisé automatique

TECHNOLOGIE BIOSÉCURISÉE DE CONVOYAGE DE PRODUITS LONGUE DISTANCE POUR LES INDUSTRIES

POURQUOI NOUS ?

NOS RÉFÉRENCES CLIENTS

POURQUOI NOUS ?

NOS RÉFÉRENCES CLIENTS